What is Transformation Induced Plasticity Steel(TRIP)?

2023-05-23

What is Transformation Induced Plasticity Steel(TRIP)?

Transformation Induced Plasticity Steel (TRIP steel) is a type of advanced high-strength steel (AHSS) that exhibits exceptional strength and ductility properties. It belongs to the class of multiphase steels that are designed to have a combination of high strength and good formability, making them ideal for automotive and structural applications.

The unique characteristic of TRIP steel lies in its microstructure, which consists of three main phases: ferrite, bainite, and retained austenite. During the manufacturing process, the steel is initially austenitized and then rapidly cooled to form a metastable austenite phase. Subsequently, when the steel is subjected to mechanical deformation, such as during forming or impact, the metastable austenite transforms into harder martensite. This phase transformation process is known as strain-induced transformation.

The strain-induced transformation of austenite into martensite in TRIP steel provides two major benefits. First, it enhances the strength of the material due to the formation of the harder martensite phase. Second, it induces a significant amount of plasticity or deformation in the material, which improves its ability to absorb energy without fracture. This combination of strength and ductility makes TRIP steel highly desirable for applications requiring lightweight and crash-resistant materials.

What are the advantages of Transformation Induced Plasticity Steel?

Transformation Induced Plasticity Steel (TRIP steel) offers several advantages over conventional high-strength steels. Its unique microstructure allows for a combination of high strength and excellent ductility, making it ideal for applications requiring lightweight and crash-resistant materials. TRIP steel exhibits a high ultimate tensile strength (UTS) and yield strength, along with good elongation and strain-hardening capacity, enabling it to withstand severe deformation without failure. It also provides superior fatigue resistance, impact toughness, and corrosion resistance. These properties make TRIP steel highly desirable for automotive and structural applications, allowing for the design of lighter vehicles while maintaining high safety standards and enabling the formation of complex shapes.

The Process of Transformation Induced Plasticity Steel

The process of producing Transformation Induced Plasticity (TRIP) steel involves specific manufacturing steps to create its unique microstructure. Here is an overview of the process:

Melting and Casting: TRIP steel is typically produced through conventional steelmaking techniques, such as electric arc furnace (EAF) or basic oxygen furnace (BOF), to melt and refine the steel. The composition is carefully controlled to achieve the desired mechanical properties.

Hot Rolling: The molten steel is cast into slabs or billets, which are then heated and hot rolled into coils or sheets. This initial rolling process helps in shaping the steel into the desired dimensions and removes any impurities.

Austenitization: The hot-rolled steel is subjected to a high-temperature heat treatment known as austenitization. The steel is heated above its critical temperature to transform its microstructure into a single-phase austenite.

Rapid Quenching: After austenitization, the steel is rapidly cooled or quenched to form a metastable austenite phase. This rapid cooling prevents the austenite from transforming into other phases, such as ferrite or pearlite.

Cold Deformation: The quenched steel is then subjected to cold deformation processes, such as cold rolling or cold forming. This mechanical deformation introduces strain and stress into the material.

Strain-Induced Transformation: During the cold deformation, the metastable austenite in TRIP steel undergoes a strain-induced transformation. The applied mechanical forces cause the austenite to transform into harder martensite, while retaining some amount of untransformed austenite.

Multiple Phases: The final microstructure of TRIP steel consists of three primary phases: ferrite, bainite, and retained austenite. The presence of retained austenite, along with the hard phases of ferrite and bainite, gives TRIP steel its unique mechanical properties.

The combination of high strength from martensite and the ability of retained austenite to undergo plastic deformation results in the excellent strength and ductility properties exhibited by TRIP steel. This unique microstructure allows the material to absorb energy and deform significantly without fracture, making it suitable for various demanding applications.

What auto parts are Transformation Induced Plasticity Steel typically used for?

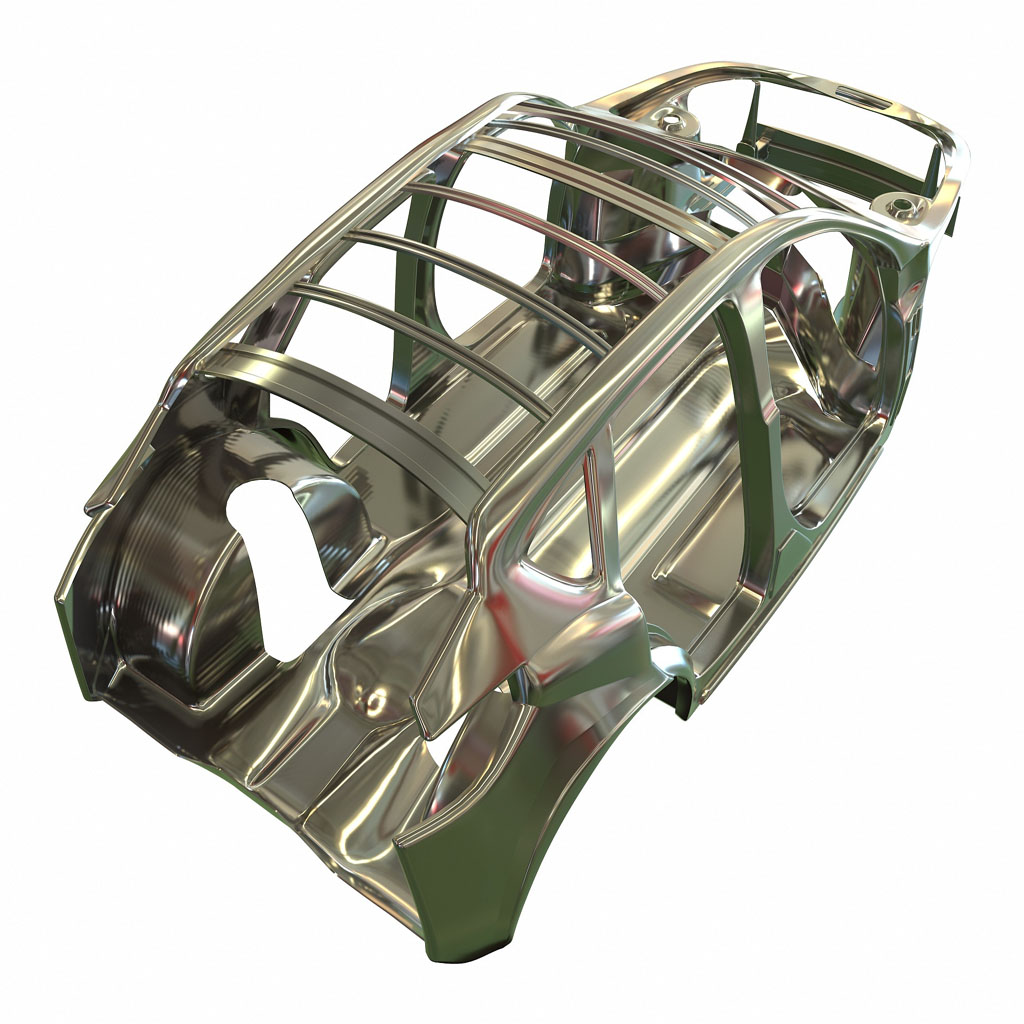

Transformation Induced Plasticity (TRIP) steel is commonly used in the automotive industry for various components that require a combination of high strength, formability, and crash resistance. Here are some auto parts where TRIP steel is typically utilized:

Structural Components: TRIP steel is employed in the manufacturing of structural components such as door beams, roof reinforcements, pillars, and side impact beams. These parts require high strength to withstand impact and provide occupant safety while maintaining lightweight design.

Bumpers and Crash Boxes: TRIP steel is utilized in the production of bumper systems and crash boxes. These parts are designed to absorb and dissipate energy during collisions, reducing the impact forces transferred to the vehicle occupants.

A-Pillars and B-Pillars: The A-pillar and B-pillar structures provide structural integrity and support to the vehicle’s roof and side structures. TRIP steel is often used in these areas due to its high strength and formability, contributing to enhanced crashworthiness and occupant protection.

Front and Rear Rails: TRIP steel is employed in the construction of front and rear rails, which form the main longitudinal structure of the vehicle’s frame. These rails provide rigidity and energy absorption capabilities, helping to protect the vehicle’s occupants in the event of a collision.

Suspension Components: Some suspension components, such as control arms and subframes, can benefit from the use of TRIP steel. The high strength and ductility of TRIP steel allow for improved performance, durability, and weight reduction in these parts.

Reinforcements: TRIP steel is utilized for various reinforcement components throughout the vehicle, including reinforcements for door panels, trunk floors, and rocker panels. These reinforcements enhance the structural integrity of the vehicle, providing additional strength and impact resistance.

The use of TRIP steel in these automotive parts allows manufacturers to achieve a balance between weight reduction, strength, and crash safety. By utilizing TRIP steel, vehicles can be designed to be lighter while maintaining high levels of occupant protection and structural integrity.