what is Mild Steel?

2023-05-26

Introduction to Mild steel

Mild steel is a type of carbon steel with low carbon content and relatively low strength. It is also known as low carbon steel or plain carbon steel. Mild steel typically contains less than 0.3% carbon by weight, making it easy to work with and shape. It is the most common form of steel used in various applications due to its affordability, versatility, and favorable mechanical properties.

Mild steel is often used in construction, automotive manufacturing, furniture production, and general fabrication. It is suitable for a wide range of structural applications, including beams, columns, plates, and bars. Mild steel is also commonly used for making pipes, tubes, and wire products.

The low carbon content of mild steel contributes to its malleability and ductility, making it easy to weld, bend, and form into different shapes. However, the low carbon content also means that mild steel has lower strength and hardness compared to other types of steel, such as high carbon steel or alloy steel. To increase its strength and durability, mild steel can be subjected to various heat treatments or combined with other elements to create different grades of steel.

What are the advantages of Mild steel?

Mild steel offers several advantages that contribute to its widespread use in various applications. Here are some of the key advantages of mild steel:

Affordability: Mild steel is relatively inexpensive compared to other types of steel, making it a cost-effective choice for many projects. Its affordability makes it accessible to a wide range of industries and applications.

Easy to work with: Mild steel has excellent formability, which means it can be easily shaped, welded, cut, and machined. Its low carbon content and malleability make it suitable for a variety of fabrication processes, allowing for customization and versatility in design.

Ductility and toughness: Mild steel exhibits good ductility, meaning it can withstand extensive deformation without fracturing. This property makes it ideal for applications that require bending, stretching, or forming. Additionally, mild steel offers good toughness, providing resistance to impact and shock loading.

Weldability: Mild steel is highly weldable, allowing for strong and reliable joints. It can be easily welded using various welding techniques, such as arc welding, MIG welding, or TIG welding. This property makes it suitable for constructing structures and components that require welding, such as buildings, bridges, and machinery.

Availability: Mild steel is readily available in large quantities, thanks to its popularity and wide usage. It can be obtained in various forms, including sheets, plates, bars, tubes, and structural sections, making it easy to source for different project requirements.

Versatility: Mild steel’s properties make it suitable for a wide range of applications across different industries. It is commonly used in construction, automotive manufacturing, shipbuilding, furniture production, appliances, and general fabrication. It can be used for structural components, machinery parts, pipelines, storage tanks, and more.

Recyclability: Mild steel is highly recyclable, making it an environmentally friendly choice. It can be melted down and reused without losing its properties, reducing the demand for new steel production and minimizing waste.

It’s important to note that while mild steel offers various advantages, it may not be suitable for applications that require high strength, resistance to extreme temperatures, or corrosion resistance. In such cases, other types of steel or alloys may be more appropriate.

The Process of Mild steel

The production process of mild steel involves several stages, starting from the extraction of iron ore and subsequent refining to obtain pure iron. The pure iron is then mixed with controlled amounts of carbon, typically less than 0.3%, and other alloying elements, if required. This mixture is melted in a blast furnace or an electric arc furnace, and impurities like sulfur, phosphorus, and excess carbon are removed. The molten metal is then cast into ingots or continuously cast into slabs, which are subsequently rolled into various forms such as sheets, plates, bars, or structural sections. The resulting mild steel products undergo further processes like heat treatment, surface treatments (such as galvanizing or painting), and fabrication techniques to meet specific requirements.

What are the common applications of mild steel?

Mild steel finds widespread use across various industries and applications due to its favorable properties and versatility. Here are some common applications of mild steel:

Construction: Mild steel is extensively used in the construction industry for structural components such as beams, columns, girders, and reinforcement bars. It is also used for roofing, fencing, stairs, and building frames.

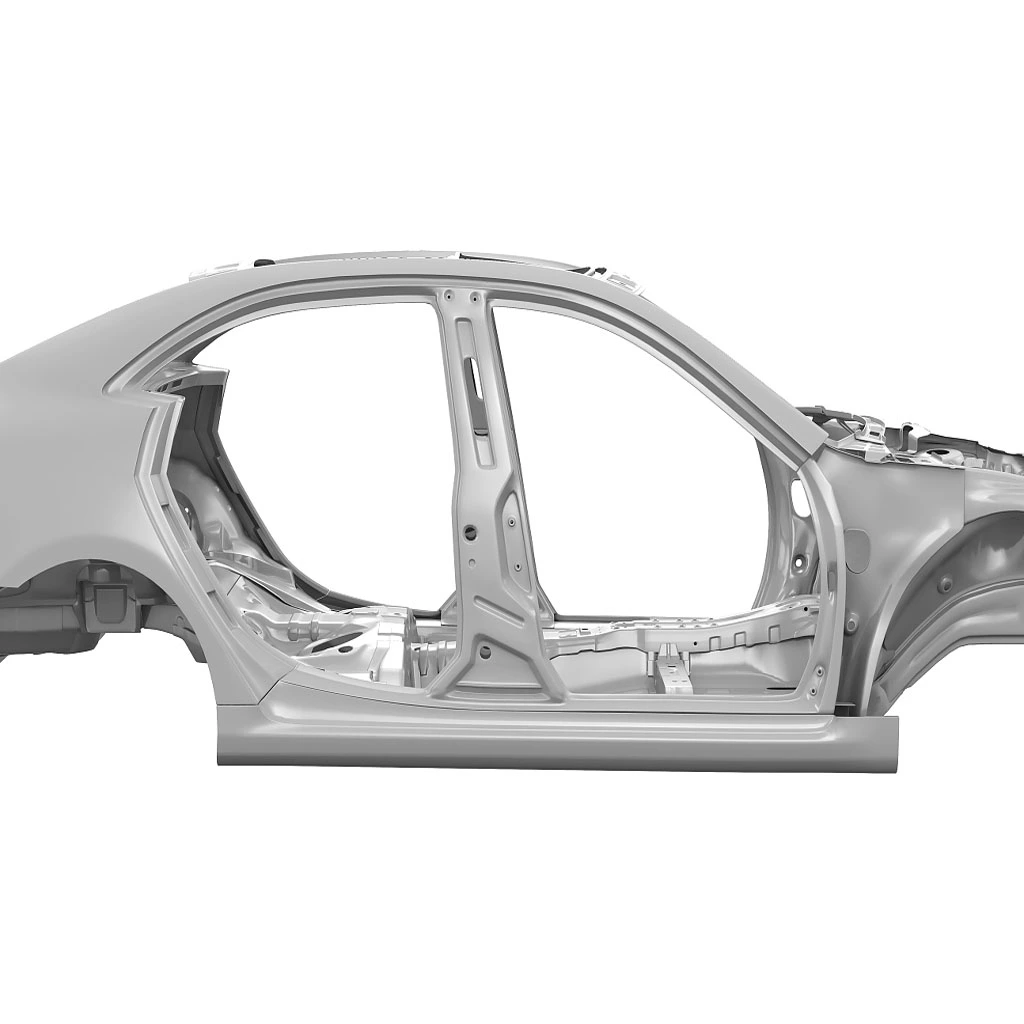

Automotive: Mild steel is utilized in the automotive sector for manufacturing various components, including chassis, body panels, engine parts, exhaust systems, and suspension components.

General Fabrication: Mild steel is widely employed in general fabrication processes for creating a wide range of products, including machinery parts, brackets, frames, brackets, and fittings. It is also used for manufacturing furniture, storage racks, and shelving systems.

Pipelines and Storage Tanks: Mild steel pipes are commonly used for water and gas pipelines, as well as in the oil industry for transporting petroleum and its byproducts. Mild steel is also used for storage tanks and containers in industries such as chemical processing and food processing.

Appliances and Household Items: Mild steel is utilized in the production of various household items and appliances, including kitchen utensils, cookware, stoves, washing machines, and refrigerators.

Shipbuilding: Mild steel is a primary material used in shipbuilding for constructing the hull, decks, and superstructures of ships and boats.

Agricultural Equipment: Mild steel is employed in the manufacturing of agricultural equipment such as tractors, plows, trailers, and irrigation systems.

Industrial Machinery: Mild steel is used in the production of industrial machinery and equipment, including conveyors, cranes, presses, gears, and machine frames.

Bridges and Infrastructure: Mild steel is utilized in the construction of bridges, flyovers, walkways, and other infrastructure projects due to its strength and durability.

Electrical Transmission: Mild steel towers and poles are used for supporting electrical transmission lines and overhead power cables.

It’s important to note that the suitability of mild steel for specific applications depends on factors such as load-bearing requirements, exposure to corrosion, and temperature conditions. In some cases, additional treatments or coatings may be necessary to enhance the performance and longevity of mild steel in specific environments.