Understanding aluminum in many ways | Aluminum alloy

2023-03-29

Aluminum is a popular metal because of its lightweight, corrosion-resistant and conductive properties. Aluminum alloys, in particular, are used in a wide variety of industries including aerospace, automotive, construction and electronics. Aluminum alloys are made by combining aluminum with other metals to improve its properties. However, not all aluminum alloys are created equal, and understanding the different types of aluminum alloys and their classifications is critical to choosing the right alloy for a particular application.

Classification of aluminum alloy

The following is a breakdown of major Aluminum Alloy categories and their classifications:

1xxx Series: These are the purest form of aluminum and contain at least 99% aluminum. They are very soft, malleable and have excellent corrosion resistance, making them suitable for applications such as packaging, electrical conductors and heat exchangers.

2xxx Series: These alloys contain copper as the main alloying element and provide high strength and excellent fatigue resistance. They are commonly used in aerospace and military applications.

3xxx Series: These alloys contain manganese as the primary alloying element and provide good strength and corrosion resistance. They are commonly used in roofing, siding and gutters in the construction industry.

4xxx series: These alloys contain silicon as the main alloying element and have good fluidity and corrosion resistance. They are commonly used for welding and brazing.

5xxx Series: These alloys contain magnesium as the main alloying element and have good formability, weldability and corrosion resistance. They are commonly used in the automotive and marine industries.

6xxx Series: These alloys contain magnesium and silicon as the main alloying elements and provide good strength, weldability, and corrosion resistance. They are commonly used for structural components in the construction industry and automotive frames and railcars in the transportation industry.

7xxx Series: These alloys contain zinc as the main alloying element and have very high strength and excellent fatigue resistance. They are commonly used in aerospace applications and the construction of high performance sports equipment.

In addition to the classification system developed by the Aluminum Association, there are international standards for aluminum alloys developed by the International Organization for Standardization (ISO) and the European Committee for Standardization (CEN).

In conclusion, understanding the different types of aluminum alloys and their classifications is important in selecting the appropriate alloy for a particular application. Each alloy has unique properties and characteristics that make it suitable for specific industries and applications.

Properties and characteristics of aluminum

1. Lightweight and high-strength: Aluminum has a low density, only about one third of steel, but its tensile strength is higher than steel. Therefore, aluminum is lighter than steel at the same strength.

2. Corrosion resistance: Aluminum has good corrosion resistance, and can form a very thin oxide film in the air to prevent further oxidation reaction, so that the surface of aluminum has good corrosion resistance.

3. Good thermal conductivity and electrical conductivity: Aluminum is a good electrical and thermal conductivity material, and its density is lighter than that of copper, so it can manufacture smaller radiators, and it can also be widely used in fields that require high electrical and thermal conductivity.

4. Strong machinability: Aluminum can be processed into complex shapes through various processing methods, such as extrusion, stretching, rolling, stamping, drilling, etc., to manufacture products of various shapes and specifications.

5. Good plasticity: Aluminum has good plasticity, and various shapes of aluminum products can be manufactured under hot and cold working conditions.

6. Environmental protection: Aluminum can be recycled and reused to reduce resource waste and environmental pollution, and has good environmental protection performance.

How is aluminum produced?

The production of aluminum is mainly realized by electrolysis. The following is the general aluminum production process:

Mining and processing of aluminum ore: Aluminum ore is mainly composed of muscovite, quartz, feldspar and other minerals, which need to be crushed, ground and soaked to obtain alumina (Al2O3).

Reduction of alumina: After mixing alumina and a certain amount of graphite powder, it is reduced to aluminum at high temperature.

Aluminum production by electrolysis: the reduced aluminum is placed in an electrolytic cell, and aluminum ions are precipitated in the electrolyte by the action of an electric current, finally forming aluminum metal. At the same time, alumina will also be reduced to oxygen and released during the electrolysis process.

Aluminum refining and product processing: refining the obtained aluminum to remove impurities such as impurities and air bubbles, and then perform product processing according to needs, such as extrusion, stretching, rolling, stamping, welding, etc., into various specifications and shapes of aluminum, aluminum alloys and aluminum products.

Application of Aluminum

Aluminum is a lightweight, corrosion-resistant, and thermally conductive metal, so it has a wide range of applications in many fields. The following are some of the main application areas of aluminum:

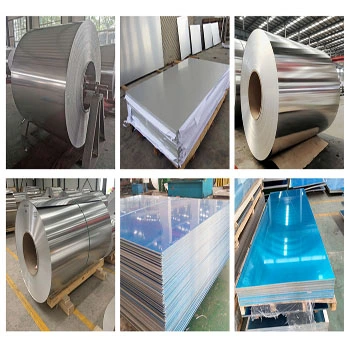

Construction and building materials: aluminum alloy profiles, aluminum film, aluminum alloy doors and windows, aluminum alloy roofs, aluminum plates, etc.

Transportation: Manufacturing and decoration of various vehicles such as automobiles, trains, aviation, ships, etc., such as automobile frames, engine covers, doors, hulls, etc.

Packaging: aluminum foil, aluminum cans, aluminum lids and other packaging materials for food, medicine, cosmetics and other products.

Electronic products: aluminum casings, heat sinks, connectors, etc. in electronic products such as mobile phones, tablet computers, TVs, and computers.

Food processing: making kitchen utensils, food processing equipment, etc.

Energy: Aluminum can be used in the manufacture of solar panels, as well as high-voltage poles for transmitting electricity, etc.

The price of aluminum and aluminum alloys in the metal industry

The price of aluminum and aluminum alloys in the metal industry

The price of aluminum and aluminum alloys is usually affected by many factors, such as the price of aluminum raw materials, production costs, supply and demand, international trade policies and so on. Accordingly, the price of aluminum and aluminum alloys may fluctuate over time and as market conditions change.

Generally speaking, the price of aluminum is relatively low, but it will vary due to different uses and processing methods. For example, the price of aluminum sheet is usually higher than that of aluminum rod, while the price of processed aluminum alloy products is higher.

The price of aluminum alloy is usually higher than that of pure aluminum, because aluminum alloy has better strength, hardness and corrosion resistance. The prices of different types of aluminum alloys will also vary. For example, the prices of commonly used 6061 aluminum alloys and 7075 aluminum alloys are usually slightly higher than other types of aluminum alloys.

It should be noted that the above prices are for reference only, and the actual prices will vary according to market conditions and specific needs.