Metallic material

Innovation | Professionalism

Integrity | Efficiency

Metallic material

Innovation | Professionalism

Integrity | Efficiency

TSG3100G-SPC270A |

TSG3100G-SPC270C |

TSG3100G-SPC270D |

TSG3100G-SPC270E |

TSG3100G-SPC270F |

TSG3100G-SPC270BH |

TSG3100G-SPC340 |

TSG3100G-SPC340BH |

TSG3100G-SPC340HR |

TSG3100G-SPC390 |

TSG3100G-SPC440 |

TSG3100G-SPC590 |

TSG3100G-SPC590DU |

TSG3100G-SPC780DU |

TSG3100G-SPC980DU |

TSG3100G-SPC980DUB |

TSG3100G-SPC1180DU |

TSG3100G-SPC390HR |

TSG3100G-SPC440HR |

TSG3100G-SPC440HY |

TSG3109G-SEACE |

TSG3109G-SEAC340 |

TSG3109G-SCGA270C |

TSG3109G-SCGA270D |

TSG3109G-SCGA270E |

TSG3109G-SCGA270F |

TSG3109G-SCGA270BH |

TSG3109G-SCGA340 |

TSG3109G-SCGA340BH |

TSG3109G-SCGA340HR |

TSG3109G-SCGA390 |

TSG3109G-SCGA440 |

TSG3109G-SCGA590 |

TSG3109G-SCGA590DU |

TSG3109G-SCGA590DUB |

TSG3109G-SCGA390HR |

TSG3109G-SCGA440HR |

TSG3109G-SCGA440HY |

TSG3109G-SCGA440SF |

TSG3109G-SHGA270C |

TSG3109G-SHGA270D |

TSG3109G-SHGA270E |

TSG3109G-SHGA370 |

TSG3109G-SHGA440 |

TSG3109G-SHGA440F |

TSG3109G-SHGA310 |

TSG3109G-SHGA400 |

TSG3109G-SHGA400HY |

TSG3109G-SHGA370J |

TSG3109G-SHGA440J |

TSG3109G-SHGA440JH |

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

TM-2011-CR1-140-270-S |

TM-2011-CR2-140-270-S |

TM-2011-CR3-140-270-S |

TM-2011-CR4-140-270-S |

TM-2011-CR5-110-260-S |

TM-2011-CR5X-140-260-S |

TM-2011-HR2-180-270-S |

TM-2011-HR3-180-270-S |

TM-2011-CR-180-290-BH-S |

TM-2011-CR-240-340-BH-S |

TM-2011-CR-300-390-BH-S |

TM-2011-CR-340-410-LA-S |

TM-2011-CR-420-480-LA-S |

TM-2011-CR-460-520-LA-S |

TM-2011-CR-500-560-LA-S |

TM-2011-CR-550-650-LA-S |

TM-2011-CR-500-560-LA/AI-S |

TM-2011-CR-550-650-LA/AI-S |

TM-2011-HR-340-420-LA-S |

TM-2011-HR-420-480-LA-S |

TM-2011-HR-460-520-LA-S |

TM-2011-HR-500-560-LA-S |

TM-2011-HR-550-610-LA-S |

TM-2011-HR-650-700-LA-S |

TM-2011-HR-660-780-LA-S |

TM-2011-HR-700-750-LA-S |

TM-2011-CR-380-450-LAS-S |

TM-2011-HR-550-650-LAS-S |

TM-2011-CR-420-590-CMn-S |

TM-2011-HR-420-590-CMn-S |

TM-2011-CR-290-490-DP-S |

TM-2011-CR-330-590-DP-S |

TM-2011-CR-440-780-DP-S |

TM-2011-CR-590-980-DP-S |

TM-2011-CR-700-980-DP-S |

TM-2011-CR-900-1180-DP-S |

TM-2011-CR-1150-1270-DP-S |

TM-2011-HR-330-580-DP-S |

TM-2011-CR-400-690-TR-S |

TM-2011-CR-450-780-TR-S |

TM-2011-CR-600-980-TR-S |

TM-2011-CR-850-1180-TR-S |

TM-2011-CR-570-780-CP-S |

TM-2011-CR-600-980-CP-S |

TM-2011-CR-850-1180-CP-S |

TM-2011-HR-660-760-CP-S |

TM-2011-HR-720-950-CP-S |

TM-2011-HR-440-580-FB-S |

TM-2011-CR-1050-1300-MS-S |

TM-2011-CR-1200-1500-MS-S |

TM-2011-CR-1350-1700-MS-S |

TM-2011-HR-900-1180-MS-S |

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

WSS-M1A367-A11 CR180 |

WSS-M1A367-A12 CR210 |

WSS-M1A367-A13 CR240 |

WSS-M1A367-A14 CR270 |

WSS-M1A367-A21 CR180B2 |

WSS-M1A367-A22 CR210B2 |

WSS-M1A367-A23 CR240B2 |

WSS-M1A367-A24 CR270B2 |

WSS-M1A367-A25 CR300B2 |

WSS-M1A367-A33 CR240LA |

WSS-M1A367-A34 CR270LA |

WSS-M1A367-A35 CR300LA |

WSS-M1A367-A36 CR340LA |

WSS-M1A367-A37 CR380LA |

WSS-M1A367-A38 CR420LA |

WSS-M1A367-A39 CR500LA |

WSS-M1A367-A44 HR270LA |

WSS-M1A367-A45 HR300LA |

WSS-M1A367-A46 HR340LA |

WSS-M1A367-A47 HR380LA |

WSS-M1A367-A48 HR420LA |

WSS-M1A367-A49 HR500LA |

WSS-M1A367-A50 HR550LA |

WSS-M1A367-A51 HR600LA |

WSS-M1A367-A52 HR700LA |

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

MBN11251-CR210LA |

MBN11251-CR240LA |

MBN11251-CR270LA |

MBN11251-CR300LA |

MBN11251-CR340LA |

MBN11251-CR380LA |

MBN11251-CR420LA |

MBN11251-CR460LA |

MBN11251-CR290Y490T-DP |

MBN11251-CR330Y590T-DP |

MBN11251-CR440Y780T-DP |

MBN11251-CR590Y980T-DP |

MBN11251-CR700Y980T-DP |

MBN11251-CR180BH |

MBN11251-CR210BH |

MBN11251-CR240BH |

MBN11251-CR280BH |

MBN11251-CR160IF |

MBN11251-CR180IF |

MBN11251-CR210IF |

MBN11251-CR240IF |

MBN11251-CR1 |

MBN11251-CR2 |

MBN11251-CR3 |

MBN11251-CR4 |

MBN11251-CR5 |

MBN11251-CR6 |

MBN11251-HR700MC |

MBN11251-HR550MC |

MBN11251-HR500MC |

MBN11251-HR460MC |

MBN11251-HR420MC |

MBN11251-HR340MC |

MBN11251-HR300MC |

MBN11251-HR500LA |

MBN11251-HR460LA |

MBN11251-HR420LA |

MBN11251-HR340LA |

MBN11251-HR300LA |

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

GMW3399M-ST-S-CR450T/250Y-DP |

GMW3399M-ST-S-CR490T/290Y-DP |

GMW3399M-ST-S-CR590T/280Y-DP |

GMW3399M-ST-S-CR590T/340Y-DP |

GMW3399M-ST-S-CR690T/550Y-DP |

GMW3399M-ST-S-CR780T/420Y-DP |

GMW3399M-ST-S-CR780T/500Y-DP |

GMW3399M-ST-S-CR980T/550Y-DP |

GMW3399M-ST-S-CR980T/700Y-DP |

GMW2M-ST-S CR1 UNCOATED |

GMW2M-ST-S CR2 UNCOATED |

GMW2M-ST-S CR3 UNCOATED |

GMW2M-ST-S CR4 UNCOATED |

GMW2M-ST-S CR5 UNCOATED |

GMW3032M-ST-S-CR180B2-UNCOATED-U |

GMW3032M-ST-S-210P-UNCOATED-U |

GMW3032M-ST-S-CR180IF-UNCOATED-U |

GMW3032M-ST-S-CR210IF-UNCOATED-U |

GMW3032M-ST-S-CR240IF-HUNCOATED-U |

GMW3032M-ST-S-CR210B2-UNCOATED-U |

GMW3032M-ST-S-CR250B2-UNCOATED-U |

GMW3032M-ST-S-CR300B2-UNCOATED-U |

GMW3032M-ST-S-CR250LA-UNCOATED-U |

GMW3032M-ST-S-CR240LA-UNCOATED-U |

GMW3032M-ST-S-CR300LA-UNCOATED-U |

GMW3032M-ST-S-HR340LA-UNCOATED-U |

GMW3032M-ST-S-CR340LA-UNCOATED-U |

GMW3032M-ST-S-CR380LA-UNCOATED-U |

GMW3032M-ST-S-CR420LA-UNCOATED-U |

GMW3032M-ST-S-HR420LA-UNCOATED-U |

GMW3032M-ST-S-HR550LA-UNCOATED-U |

GMW3032M-ST-S-HR650LA-UNCOATED-U |

GMW2M-ST-S CR1 GMW11M EG50G50GE |

GMW2M-ST-S CR2 GMW11M EG50G50GE |

GMW2M-ST-S CR3 GMW11M EG50G50GE |

GMW2M-ST-S CR4 GMW11M EG50G50GE |

GMW2M-ST-S CR5 GMW11M EG50G50GE |

GMW2M-ST-S CR1 GMW11M EG60G60GE |

GMW2M-ST-S CR2 GMW11M EG60G60GE |

GMW2M-ST-S CR3 GMW11M EG60G60GE |

GMW2M-ST- S CR4 GMW11M EG60G60GE |

GMW2M-ST-S CR5 GMW11M EG60G60GE |

GMW2M-ST-S CR1 EG50G50GE |

GMW2M-ST-S CR2 EG50G50GE |

GMW2M-ST-S CR3 EG50G50GE |

GMW2M-ST-S CR4 EG50G50GE |

GMW2M-ST-S CR5 EG50G50GE |

GMW2M-ST-S CR1 EG60G60GE |

GMW2M-ST-S CR2 EG60G60GE |

GMW2M-ST-S CR3 EG60G60GE |

GMW2M-ST-S CR4 EG60G60GE |

GMW2M-ST-S CR5 EG60G60GE |

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

GS93032-2-CR1 | ||

GS93032-2-CR2 | ||

GS93032-2-CR3 | ||

GS93032-2-CR4 | ||

GS93032-2-CR5 | ||

GS93032-2-HR2 | ||

GS 93032-4-CR180BH | ||

GS 93032-4-CR210BH | ||

GS 93032-4-CR240BH | ||

GS 93032-4-CR280BH | ||

GS 93032-5-CR180IF | ||

GS 93032-5-CR180IF-CR210IF | ||

GS 93032-5-CR180IF-CR240IF | ||

GS 93032-3-CR210LA | ||

GS 93032-3-CR240LA | ||

GS 93032-3-CR270LA | ||

GS 93032-3-CR340LA | ||

GS 93032-3-CR380LA | ||

GS 93032-3-CR420LA | ||

GS 93032-3-HR300LA | ||

GS 93032-3-HR340LA | ||

GS 93032-3-HR380LA | ||

GS 93032-3-HR420LA | ||

GS 93032-3-HR460LA | ||

GS 93032-3-HR500LA | ||

GS 93032-3-HR300MC | ||

GS 93032-3-HR340MC | ||

GS 93032-3-HR380MC | ||

GS 93032-3-HR420MC | ||

GS 93032-3-HR460MC | ||

GS 93032-3-HR500MC | ||

GS 93032-7-CR250Y440T--DP | ||

GS 93032-7-CR290Y490T--DP | ||

GS 93032-7-CR330Y590T--DP | ||

GS 93032-7-CR440Y780T--DP | ||

GS 93032-7-CR700Y980T--DP | ||

GS 93032-7-HR330Y580T--DP | ||

GS 93032-8-CR570Y780T-- CP | ||

GS 93032-8-CR660Y780T--CP | ||

GS 93032-8-HR660Y760T--CP | ||

GS 93032-6-HR280MB | ||

GS 93032-6-HR280MB-CR300MB | ||

GS 93032-6-HR280MB-CR380MB | ||

GS 93032-9-CR400Y690T-TR | ||

GS 93032-10 CR950Y1200T-MS | ||

GS 93032-10 HR900Y1180T--MS |

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

VW 50065 CR1 |

VW 50065 CR2 |

VW 50065 CR3 |

VW 50065 CR4 |

VW 50065 CR5 |

VW 50065 CR6 |

VW 50065 HR2 |

VW 50065 CR210LA |

VW 50065 CR240LA |

VW 50065 CR270LA |

VW 50065 CR300LA |

VW 50065 CR340LA |

VW 50065 CR380LA |

VW 50065 CR420LA |

VW 50065 CR460LA |

VW 50065 HR300LA |

VW 50065 HR340LA |

VW 50065 HR420LA |

VW 50065 HR460LA |

VW 50065 HR500LA |

VW 50065 HR300MC |

VW 50065 HR340MC |

VW 50065 HR420MC |

VW 50065 HR460MC |

VW 50065 HR500MC |

VW 50065 HR550MC |

VW 50065 HR700MC |

VW 50065 CR160IF |

VW 50065 CR180IF |

VW 50065 CR210IF |

VW 50065 CR240IF |

VW 50065 CR180BH |

VW 50065 CR210BH |

VW 50065 CR240BH |

VW 50065 CR210P |

VW 50065 CR240P |

VW 50065 CR290Y490T-DP |

VW 50065 CR330Y590T-DP |

VW 50065 CR440Y780T-DP |

VW 50065 CR590Y980T-DP |

VW 50065 CR700Y980T-DP |

VW 50065 HR330Y580T-DP |

VW 50065 CR400Y690T-TR |

VW 50065 CR450Y780T-TR |

VW 50065 CR570Y780T-CP |

VW 50065 CR780Y980T-CP |

VW 50065 HR660Y760T-CP |

VW 50065 HR900Y1180T-MS |

VW 50065 HR300Y450T-FB |

VW 50065 HR440Y580T-FB |

VW 50065 HR600Y780T-FB |

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

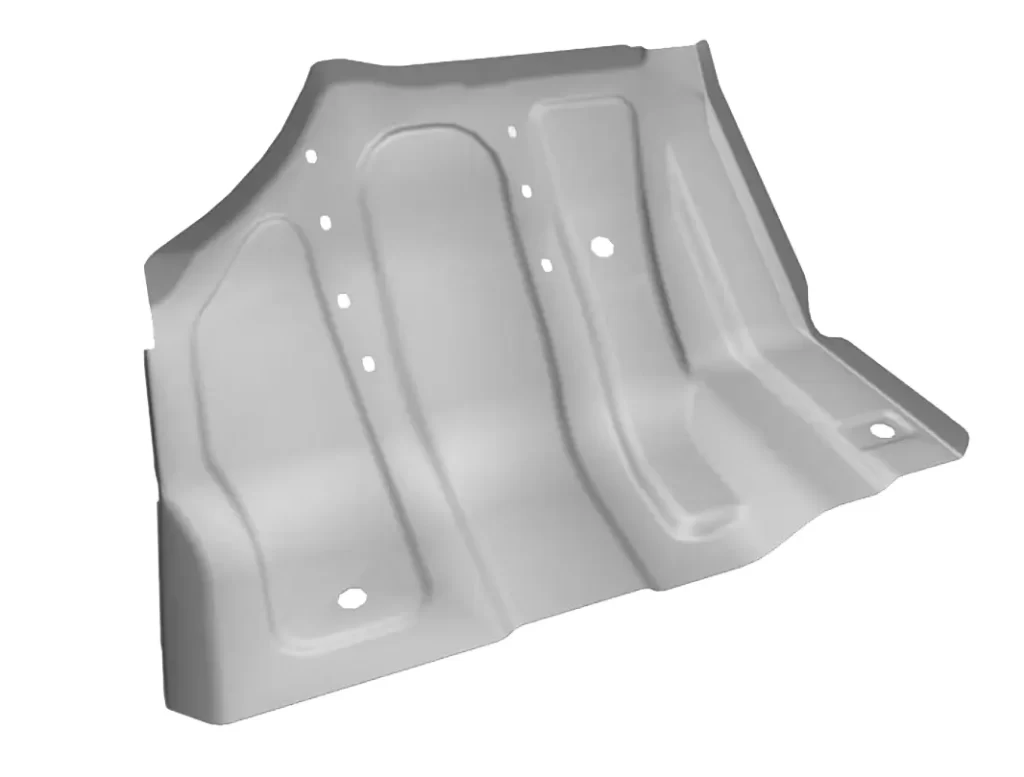

Front floor pan is an automotive part that is a metal plate on the underside of the vehicle, usually under the front seats. It is part of the vehicle's chassis that supports and protects the underbody and underbody components of the vehicle, such as the engine, transmission and suspension. It is usually made of steel or aluminum for strength and corrosion resistance. If the front floor panel is damaged or corroded, it may affect the structural integrity and stability of the vehicle, resulting in driving safety concerns.

The steel contains a specific quantity of solid solution carbon and nitrogen atoms, and its strength can be improved by introducing strengthening elements like manganese and phosphorus. It is commonly used for the outer body of automobiles, as it undergoes age hardening, after and baking at a particular temperature, leading to an increase in its yield strength. The structure of the steel is ferrite.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC180BD+Z | 180-240 | 300-360 | ≥34% | ≥1.5 | ≥0.16 | ≥30 |

Grade: HC180BD+Z

C(max): 0.04

Mn(max): 1

Si(max): 0.5

Dual phase steel is a preferred material for automotive structural parts because of its microstructure, which consists primarily of ferrite and martensite. The martensite structure is dispersed in the ferrite matrix in the form of islands. This steel has a low yield work ratio, a high hardening index, and a bake hardening value.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC550/980DPD+Z | 550-730 | ≥980 | ≥10% | - | - | - |

Grade: HC550/980DPD+Z

C(max): 0.23

Mn(max): 3

Si(max): 1

The microstructure of dual phase steel, which is mainly composed of ferrite and martensite, makes it a desirable material for automotive structural parts. The martensite structure is dispersed in the form of islands within the ferrite matrix. Dual phase steel has a low yield ratio, high work hardening index, and bake hardening value, all of which contribute to its preferred usage in automotive structural applications.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC420/780DPD+Z | 420-550 | ≥780 | ≥17% | - | - | - |

Grade: HC420/780DPD+Z

C(max): 0.18

Mn(max): 2.5

Si(max): 0.8

High-strength carbon structural steel is a variety of steel that achieves increased strength by incorporating small amounts of alloy elements like Si and Mn, primarily through the process of solid solution strengthening. The primary microstructure of this type of steel is composed of ferrite and pearlite.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| B280VK | 280-400 | ≥440 | ≥29% | - | - | - |

Grade: B280VK

C(max): 0.15

Mn(max): 2

Si(max): 0.5

In the front floor assembly of a car, "center channel" usually refers to the central tunnel cover, also known as the center console tunnel cover. The cover panel sits on the floor between the front seats and covers the center tunnel, protecting the vehicle's drivetrain and other parts from external damage.

The process of creating hot-formed steel involves heating a billet above its austenitization temperature, holding it for a specific period, and then pressing and quenching it to form a martensitic structure. This process results in high strength and toughness of the part, effectively enhancing the part's anti-collision performance. Hot-formed steels are primarily used for body structural parts, particularly for intrusion-proof security structural parts.

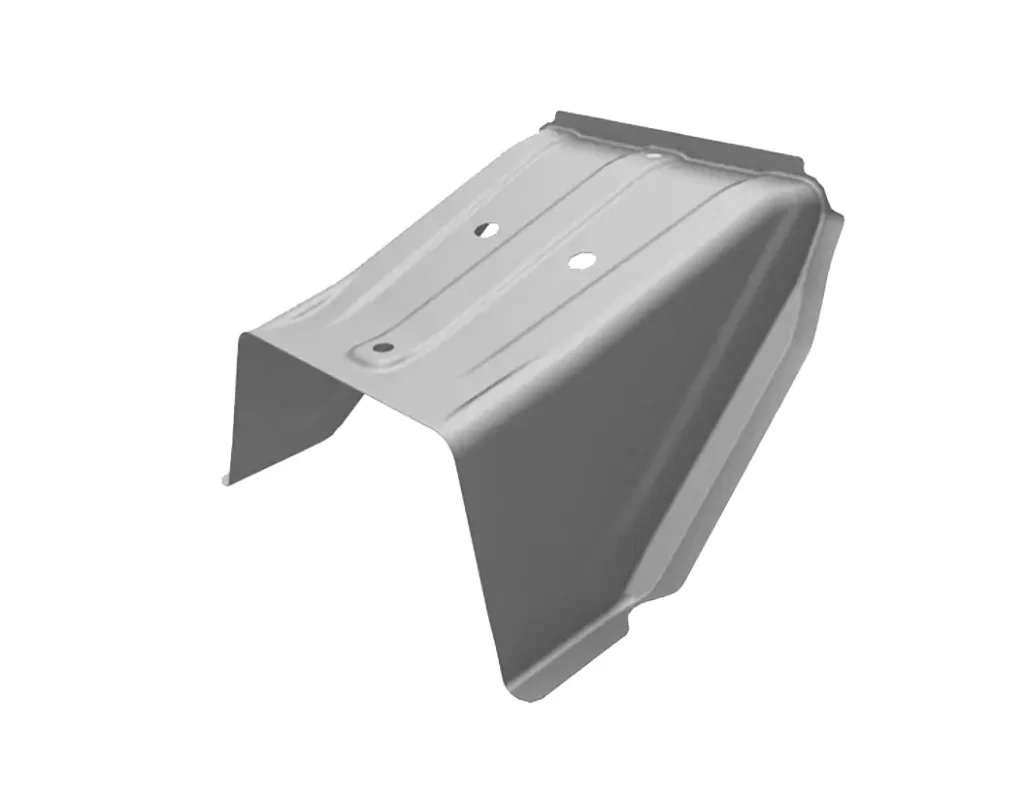

"Second crossmember" refers to a structural component in the front floor assembly of a vehicle. It is typically a horizontal beam that runs across the vehicle's underbody and provides support for the vehicle's suspension system. The second crossmember is positioned behind the first crossmember, which is located closer to the front of the vehicle. Together, these crossmembers help to distribute the weight of the vehicle and absorb impact forces during a collision.

Dual phase steel is a favored material for automotive structural parts due to its microstructure, which is primarily composed of ferrite and martensite. Within the ferrite matrix, the martensite structure is dispersed in the form of islands. Dual phase steel boasts a low yield ratio, high work hardening index, and bake hardening value, all of which make it highly suitable for use in automotive structural applications.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC420/780DPD+Z | 420-550 | ≥780 | ≥17% | - | - | - |

Grade: B280VK

C(max): 0.18

Mn(max): 2.5

Si(max): 0.8

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

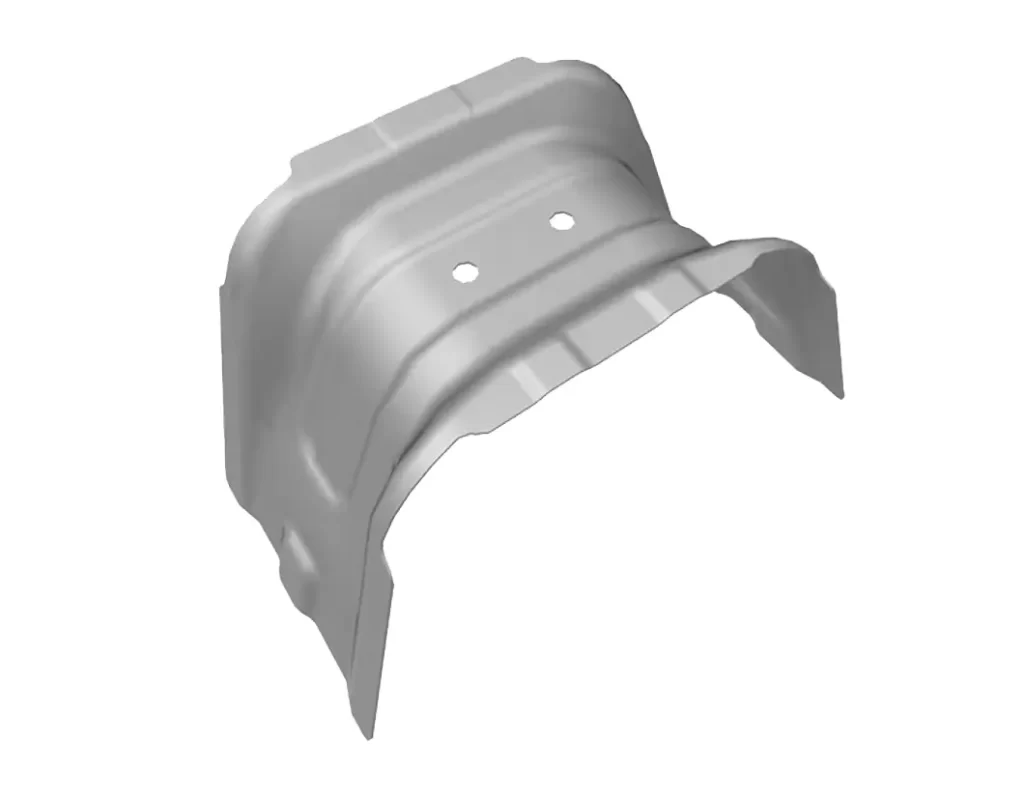

The front fender side reinforcement panel is a component of a vehicle's body structure that is located on the front fender of the car. It is designed to provide additional strength and support to the front fender, especially during a collision.

The front fender side reinforcement panel is typically made of high-strength steel or aluminum alloy, and it is bolted directly onto the car's frame or unibody structure. It is usually located behind the outer fender panel and in front of the inner fender panel.

In the event of a collision, the front fender side reinforcement panel helps to distribute the impact of the collision across the car's structure, reducing the risk of injury to the passengers inside the vehicle. It also helps to prevent damage to the car's engine and other critical components.

Quench & Partitioning (Q&P) steel is a type of steel that is primarily based on martensite, but also contains a certain amount of ferrite and 8%-12% of retained austenite in its microstructure. This unique combination of phases provides the steel with a high level of strength, as well as excellent plasticity and formability.

One of the key advantages of Quench & Partitioning (Q&P) steel is its ability to utilize the transformation-induced plasticity effect of retained austenite during deformation. This means that the retained austenite is able to undergo a transformation into martensite during plastic deformation, which results in an increase in work hardening performance and elongation level. This effect helps to improve the material's ability to resist deformation and maintain its shape during use.

Compared to high-strength steel of the same strength level, Quench & Partitioning (Q&P) steel has better plasticity and formability. This means that it is easier to form into complex shapes, making it a popular choice for a variety of applications, including automotive, construction, and manufacturing industries.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC600/980QPD+Z | 600-850 | ≥980 | ≥15% | - | - | - |

Grade: HC600/980QPD+Z

C(max): 0.25

Mn(max): 3

Si(max): 2.5

Dashboard brackets are an essential component of a vehicle's interior structure that supports the dashboard or instrument panel. They are typically made of high-strength steel or aluminum alloy and are designed to provide stability and rigidity to the dashboard assembly.

Dashboard brackets are located behind the dashboard and are bolted to the vehicle's frame or body structure. They are designed to withstand the weight of the dashboard and any accessories mounted on it, such as the steering column, air vents, and gauges.

In addition to providing structural support, dashboard brackets also play a critical role in ensuring the safety of passengers in the event of a collision. They help to distribute the impact of a collision across the vehicle's frame, reducing the risk of injury to occupants.

Double-phase steel, also known as DP steel, is a type of high-strength steel used in the automotive industry. It is characterized by its microstructure, which is composed of mainly ferrite and martensite tissues. The martensite tissue is distributed on the ferrite body in island-like formations.

The combination of these two microstructures gives DP steel its unique mechanical properties, including a low flexion ratio, high processing sclerosis index, and high baking hardening value. This makes it an ideal material for automotive structure parts that require high strength and durability.

DP steel is commonly used in automotive body panels, such as doors, hoods, and fenders, as well as in structural components like chassis and suspension systems. Its high strength-to-weight ratio allows for lighter weight vehicles that are more fuel-efficient and have better performance.

Additionally, DP steel offers excellent formability and weldability, making it easy to manufacture into complex shapes and structures. It also has good resistance to corrosion and fatigue, making it a reliable choice for automotive applications.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC420/780DP | 420-550 | ≥780 | ≥15% | - | - | - |

Grade: HC420/780DP

C(max): 0.18

Mn(max): 2.5

Si(max): 0.8

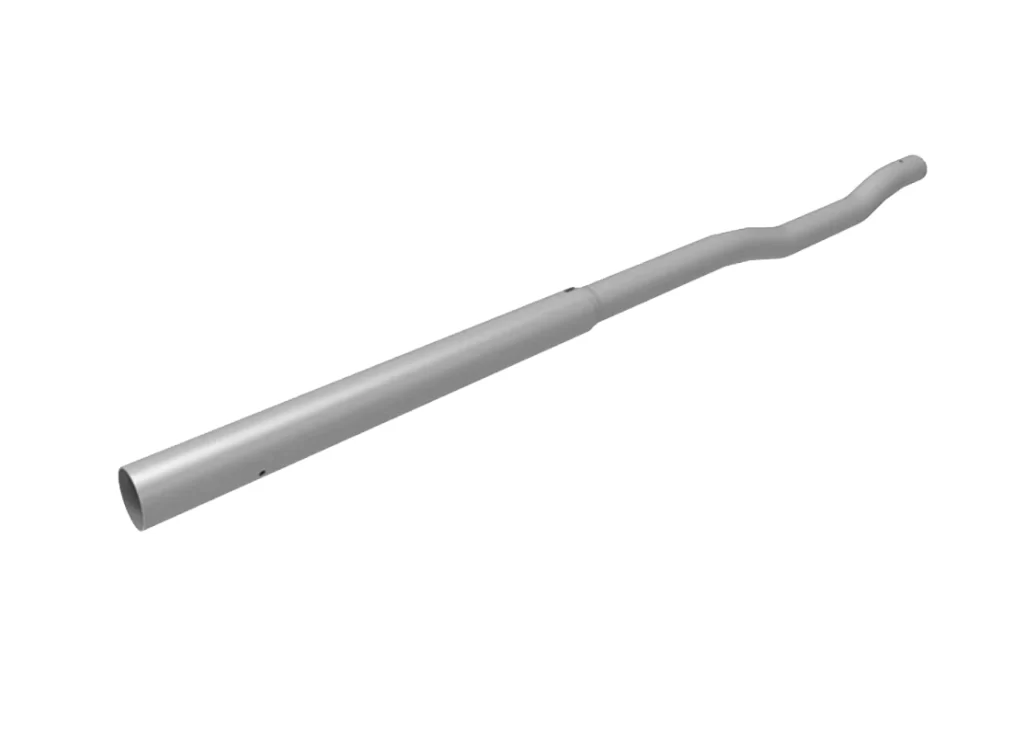

The automotive component "front longitudinal beam" refers to a longitudinal beam located at the front part of the vehicle's frame, typically made of high-strength steel. It connects the front structures of the vehicle, such as the engine support and front suspension system, and is an essential component of the vehicle's frame.

The front longitudinal beam plays a critical role in absorbing, transmitting, and dispersing collision forces during vehicle operation, helping to protect the safety of vehicle occupants. Its design and manufacture must comply with strict standards and requirements to ensure that it can withstand and distribute forces during collisions and protect the safety of the vehicle and its occupants.

In addition to safety considerations, the design of the front longitudinal beam must also take into account factors such as vehicle weight, structural stability, and reliability.

Quench & Partitioning (Q&P) steel is a type of steel that contains martensite as its primary component, along with ferrite and retained austenite in its microstructure. This unique combination of phases offers the steel excellent plasticity, formability, and high strength.

The most significant advantage of Q&P steel is the transformation-induced plasticity effect of retained austenite, which occurs during deformation. This effect transforms the retained austenite into martensite, resulting in increased work hardening performance and elongation level. This helps improve the steel's ability to resist deformation and maintain its shape during use.

Q&P steel offers better plasticity and formability than high-strength steel of the same strength level. This makes it a popular choice in various industries, such as automotive, construction, and manufacturing, where complex shapes are required.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC600/980QPD+Z | 600-850 | ≥980 | ≥15% | - | - | - |

Grade: HC600/980QPD+Z

C(max): 0.25

Mn(max): 3

Si(max): 2.5

DP steel, also known as double-phase steel, is a high-strength steel commonly used in the automotive industry. Its microstructure comprises mainly of ferrite and martensite tissues, with the martensite tissue distributed in island-like formations on the ferrite body.

DP steel's unique mechanical properties, including a low flexion ratio, high processing sclerosis index, and high baking hardening value, make it an ideal material for automotive structure parts that require high strength and durability. It is commonly used in body panels such as doors, hoods, and fenders, as well as in structural components like chassis and suspension systems, due to its high strength-to-weight ratio, which allows for lighter weight vehicles that are more fuel-efficient and have better performance.

DP steel also offers excellent formability and weldability, making it easy to manufacture into complex shapes and structures. It has good resistance to corrosion and fatigue, making it a reliable choice for automotive applications.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC420/780DPD+Z | 420-550 | ≥780 | ≥17% | - | - | - |

Grade: HC420/780DPD+Z

C(max): 0.18

Mn(max): 2.5

Si(max): 0.8

The front floor longitudinal beam rear section is a component of a vehicle's chassis that runs longitudinally along the length of the car's floor. It is located towards the back of the car and is part of the front floor structure. The front floor longitudinal beam rear section provides structural support and rigidity to the vehicle's chassis.

This beam is typically made of high-strength steel and is designed to absorb and distribute impact forces in the event of a collision. It helps to protect the occupants of the vehicle by ensuring that the passenger compartment remains intact and by minimizing the risk of the vehicle collapsing or deforming during a crash.

Double-phase (DP) steel is a type of high-strength steel that is widely used in the automotive industry. Its microstructure consists of ferrite and martensite tissues, with the latter forming island-like structures on the former. DP steel is favored for its unique mechanical properties, such as low flexion ratio, high processing sclerosis index, and high baking hardening value, which make it an excellent material for automotive components that require superior strength and durability. This type of steel is commonly utilized in body panels like fenders, doors, and hoods, as well as in structural parts including suspension systems and chassis, because of its high strength-to-weight ratio, which allows for lightweight vehicles that are fuel-efficient and high-performing.

DP steel also exhibits exceptional formability and weldability, making it easy to shape and join into complex structures. Its resistance to corrosion and fatigue further enhances its reliability and longevity in automotive applications.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC420/780DPD+Z | 420-550 | ≥780 | ≥17% | - | - | - |

Grade: HC420/780DPD+Z

C(max): 0.18

Mn(max): 2.5

Si(max): 0.8

The front longitudinal beam outer panel is a component of the front longitudinal beam of a vehicle's chassis. This beam is an essential structural component of a vehicle's chassis, running longitudinally along the car's floor to provide support and rigidity to the car's body.

The front longitudinal beam outer panel is the outermost layer of the front longitudinal beam and acts as a protective covering for the beam. It helps to protect the beam from damage due to road debris, environmental factors, and collisions.

The outer panel is typically made of high-strength steel or other materials that offer good impact resistance and durability. It is designed to withstand high forces and impacts that may occur during the operation of the vehicle, such as collisions or rough road conditions.

Quench and Partitioning (Q&P) steel is a steel variant that features martensite as its primary constituent, in conjunction with ferrite and retained austenite in its microstructure. This particular combination of phases confers exceptional attributes to the steel, such as impressive formability, plasticity, and a superior level of strength.

Phase transformation induced plasticity (TRIP) steel has a microstructure consisting of ferrite, bainite, and retained austenite. During the forming process, the retained austenite undergoes transformation into martensite, which enhances the material's plastic deformation ability, leading to a balance between high strength and plasticity. This material has excellent characteristics, including a high "n" value, good formability, and high impact absorption energy.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC600/980QP GI | 600-850 | ≥980 | ≥15% | - | - | - |

| HC400/690TRD+Z | 400-510 | ≥690 | ≥26% | - | ≥0.19 | - |

Grade: HC400/690TRD+Z

C(max): 0.24

Mn(max): 2.2

Si(max): 2

Grade: HC600/980QP GI

C(max): 0.25

Mn(max): 3

Si(max): 2.5

The twinning-induced plasticity (TWIP) steel is a fully austenitic steel with high carbon, manganese, and aluminum content, which is capable of dynamic refinement through twinning. It exhibits extremely high work hardening ability due to the dynamic refinement induced by twinning, resulting in a single-phase austenitic microstructure. TWIP steel possesses both ultra-high strength and exceptional ductility, with a high strain-hardening capacity of over 50 GPa%.

The microstructure of dual-phase steel is mainly composed of ferrite and martensite, with the latter dispersed in an island-like pattern within the former. This unique microstructure endows the steel with a low yield-to-tensile strength ratio, high work hardening index , and bake hardening value, making it a preferred material for automotive structural components.

The steel used in hot forming processes involves heating the billet above the austenitization temperature, holding it at a specific temperature for a period of time, and then pressing and quenching it to form a martensitic structure. This imparts high strength and toughness to the resulting parts , effectively enhancing their anti-collision properties. Hot-formed steels are primarily utilized in the production of body structural components, particularly in safety-related structural parts that prevent intrusion.

Dual-phase steel has a microstructure primarily consisting of ferrite and martensite, with the latter dispersed in an island-like pattern within the former. This distinctive microstructure results in a low yield-to-tensile strength ratio, high work hardening index, and bake hardening value, making it an ideal material for manufacturing automotive structural components.

Quench and Partitioning (Q&P) steel is a type of steel that consists primarily of martensite, along with ferrite and retained austenite in its microstructure. This unique combination of phases gives the steel exceptional properties, including excellent formability, plasticity, and high strength.

Dual-phase steel is a type of steel that contains a microstructure mainly composed of ferrite and martensite. The martensite is distributed in a pattern resembling islands within the ferrite. This unique microstructure provides the steel with a low yield-to-tensile strength ratio, high work hardening index, and bake hardening value. As a result, it is an excellent material for producing structural components for automobiles.

Carbon structural high-strength steel is a category of steel that gains strength by incorporating small quantities of alloying elements, such as Si and Mn. This strength is primarily achieved through solid solution strengthening, with the primary structure being a combination of ferrite and pearlite.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| B280VK | 280-400 | ≥440 | ≥29% | - | - | - |

Grade: B280VK

C(max): 0.15

Mn(max): 2

Si(max): 0.5

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!

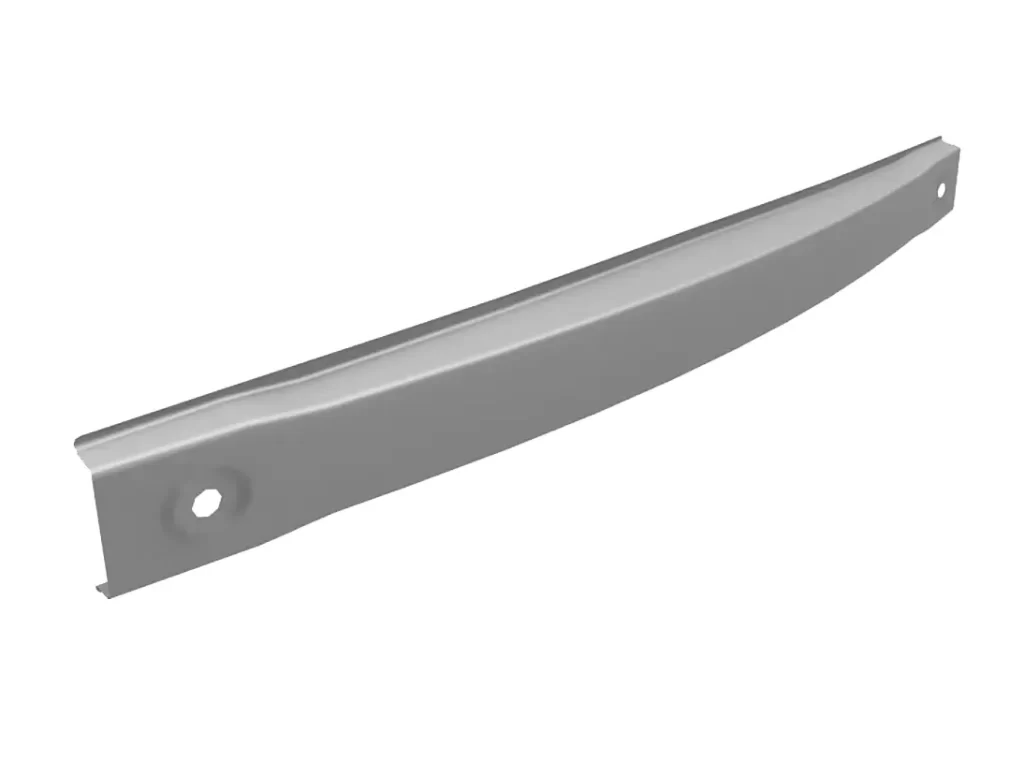

A front anti-collision beam, also known as a front bumper beam or front impact bar, is an important component of a vehicle's safety system. It is a horizontal metal bar that is installed inside the front bumper of a car or truck, and it is designed to absorb and distribute the energy from a collision, helping to protect the occupants of the vehicle.

The front anti-collision beam is typically made of high-strength steel and is bolted securely to the vehicle's frame. In a collision, the beam is designed to absorb the impact and prevent the energy from being transferred directly to the passenger compartment of the vehicle. Instead, the energy is dispersed throughout the entire structure of the vehicle, reducing the risk of injury to the occupants.

Steels for hot forming, also known as hot stamping steels, are a type of steel that is processed using a specific heat treatment method to achieve high strength and high toughness. The process involves heating the steel billet above the austenitization temperature, which is the temperature at which the steel transforms into a face-centered cubic crystal structure. The billet is then held at that temperature for a certain period of time to fully transform the microstructure.

After the holding time, the billet is rapidly cooled or quenched to room temperature to form a martensitic structure. This process of quenching and forming a martensitic structure results in a high-strength steel with excellent ductility and toughness. The high-strength and high- Toughness properties of the steel make it ideal for use in body structural parts, especially in intrusion-proof safety structural parts, where it is important to have materials that can withstand high impact loads.

The use of steels for hot forming in body structural parts has been widely adopted in the automotive industry due to its effectiveness in improving anti-collision performance.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC950/1300HS | 950-1250 | 1300-1700 | ≥5% | - | - | - |

Grade: HC950/1300HS

C(max): 0.20-0.25

Mn(max): 1.0-1.4

Si(max): 0.4

The front anti-collision beam energy-absorbing box is an important safety feature in modern automobiles. It is a part of the car's body structure that is designed to absorb the impact energy of a collision to protect the passengers inside the vehicle.

The front anti-collision beam is typically made of high-strength steel and is located at the front of the car, behind the bumper. The energy-absorbing box is an integral part of the anti-collision beam and is designed to crumple and deform upon impact, absorbing the energy of the collision and reducing the force of the impact on the passengers.

The energy-absorbing box works by compressing and deforming upon impact, which dissipates the energy of the collision and reduces the force of the impact on the passengers. This helps to reduce the risk of injury in the event of a collision, as well as to minimize the damage to the car itself.

Low-alloy high-strength steel is a variety of steel that includes small quantities of alloying components, such as vanadium, titanium, and niobium. These elements are added individually or in combination to low-carbon steel to create carbon and nitrogen compound particles for precipitation. These particles aid in strengthening the steel, increasing its durability, and resistance to deformation.

Besides boosting the steel's strength, microalloying components also refine the steel's grain structure. This refinement enhances the uniform distribution of the alloying components and helps avoid the creation of large, brittle grains. As a result, the steel is both strong and ductile, meaning it can endure high levels of stress without breaking or deforming.

Low-alloy high-strength steel is sought-after because of its excellent weldability, which means it can be welded without compromising its strength or durability. This makes it a popular choice for applications requiring welding, such as in the construction of bridges, buildings, and pipelines.

Typically, the microstructure of low-alloy high-strength steel consists of ferrite and a small amount of carbide. Ferrite is a type of iron that is relatively soft and ductile, whereas carbide is a hard, brittle compound that includes carbon and other elements.

| Grade | YS(MPa) | TS(MPa) | EL(%) | r | n | BH2(MPa) |

| HC340LAD+Z | 340-420 | 410-510 | ≥21% | - | - | - |

Grade: HC340LAD+Z

C(max): 0.11

Mn(max): 1

Si(max): 0.5

Our company: Hengqiao(Shanghai) International Trading Limited

The company's main business is general GMW standard, Fiat EFE standard, Volvo VDA standard, Nissan NEN standard, Volkswagen VW50065, Ford WSS-M and other standard series of automotive steel.

Looking forward to your inquiry!